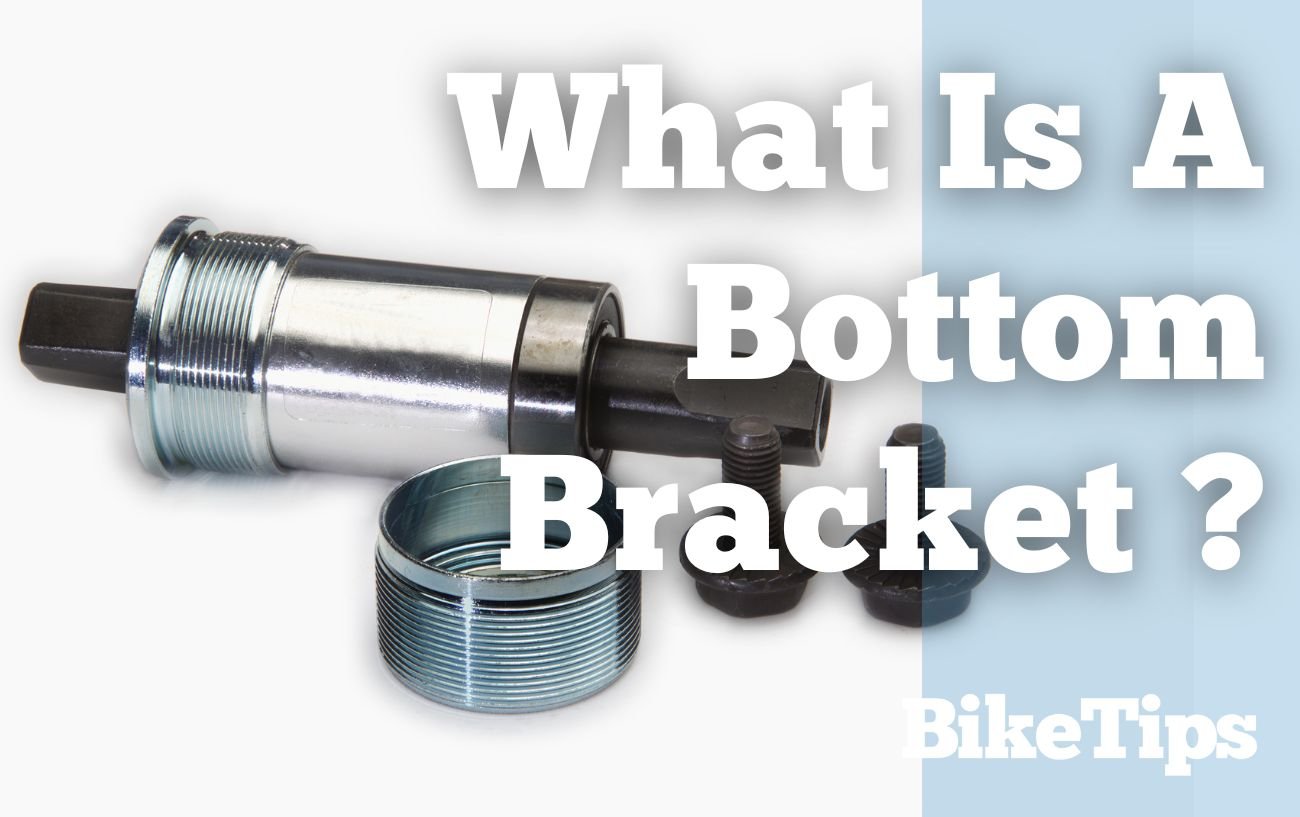

The bottom bracket is a key component in making your bike function. It contains a set of bearings, and acts as the interface between the bike’s frame and the crankset, which the pedals are attached to via the crank arms.

Put simply, the bottom bracket is what allows your pedals to turn.

The bottom bracket has become something of a mechanical hydra: innovate on one model, and two come along to take its place.

And when it’s time to replace yours, you need to do your homework.

What started as a near-universal component is now a compatibility minefield of different types and standards, and without proper research, home mechanics will be caught out.

Fear not! We’ll be your guide to the confusing world of bottom brackets.

In this article, we’ll be covering:

- What Is A Bottom Bracket On A Bicycle?

- 4 Signs Your Bottom Bracket Needs Replacing

- Replacing Your Bottom Bracket

- Bottom Bracket Standard Types Explained

- Finding Compatible Parts

Ready to dive into what is a bike bottom bracket?

Let’s dive in!

What Is A Bottom Bracket On A Bicycle?

Put simply, the bottom bracket is the interface between your frame and pedals. It’s what allows the pedals to spin.

At the lowest point of your bike frame is the bottom bracket shell, a small circular space which the bottom bracket is threaded or pressed into.

With the bottom bracket secured in the shell, the crank is attached to (or through) the bottom bracket, meaning the crank can rotate freely against the frame as you pedal.

4 Signs Your Bottom Bracket Needs Replacing

#1. You’ll Hear And Feel It

This is the simple answer. The squeaky wheel gets the grease, as the saying goes.

A new bottom bracket will be silent and slick as oil, or close to it, whilst a worn-out bottom bracket will make grinding or clicking noises and will feel rougher as you pedal through it.

But this is all about intuition, and there are more scientific approaches.

#2. Wiggle Your Crank

Simply take hold of your crank and give it a gentle wiggle: it shouldn’t be moving laterally.

Assuming all is well with your bottom bracket your crank will only move parallel to your frame.

#3. Listen To Your Bottom Bracket

Next, take your chain off your crank, to remove other noises, and then give your crank a good spin and listen.

As mentioned, clicking or grinding indicates something is wrong.

But bear in mind that proper maintenance rarely means perfection, and a very small noise is probably acceptable.

#4. Feel For Grinding

Finally, you’ll want to check for inconsistency, or worse, grinding, in your bottom bracket’s rotation.

A good method here is to hold your seatpost in one hand and rotate your crank with the other and pay attention to what you feel.

A worn bottom bracket will develop backlash, or play, causing force to be exerted on your shell and frame inconsistently.

As you rotate the crank, you’ll feel play as little “jumps”, causing vibrations through your seat post.

Allowed to progress, wear and tear will start to cause grinding. And this will be felt by variable resistance as you rotate your crank and a lot of vibration in the frame, and you’ll probably have already felt this whilst pedaling.

Again, you shouldn’t want or expect perfection here, but bear in mind that this grinding will begin to cause wear to also act on your bottom bracket shell over time.

With these four methods, you should be able to detect any issues easily and know when to replace your bottom bracket.

Replacing Your Bottom Bracket

Bottom brackets are generally service items, designed to be replaced rather than repaired or altered. So, it’s worth learning how to replace a bike’s bottom bracket.

Also important to note: upgrading or replacing your bottom bracket is unlikely to affect your riding.

Unless seriously worn out, the bottom bracket’s role in the ecosystem of the bicycle is simply too small to have a perceptible impact during your rides.

But, if you leave it too long to replace your bottom bracket, it may become seized into the shell. So make sure you do make the replacement when the time comes.

Plus if you’re a competitive cyclist, inefficiency from a heavily-worn bottom bracket is a “marginal gain” that’s easily worth addressing.

Bottom Bracket Standard Types Explained

As designs have changed over the years, home mechanics can be left in compatibility hell.

Engineering bicycles is no straightforward affair – they can be studied in undergraduate engineering after all.

Various innovations and reiterations mean the last thirty years have seen the introduction of a lot of different types of bottom brackets.

And nearly all of these technologies are still in circulation, known as different “standards”. Rather than peaceful coexistence, we have an intricate compatibility labyrinth.

We’ll go through it chronologically, so you’ll know each bottom bracket standard and how they differ from the rest.

Threaded Bottom Brackets

Bottom brackets were first introduced to replace cotter pins. Cotter pins are still used on some children’s bikes and are common in developing countries.

On higher-end bicycles, the square tapered axle was the standard bottom bracket model until roughly 30 years ago.

This bottom bracket threaded into your frame, with sealed bearings placed in a cartridge container around a spindle, while the crank is mounted to a square tapered axle.

Mounting and demounting the crank to the threaded bottom bracket required a pretty bulky Allen key.

This was improved somewhat with the introduction of Shimano’s Octalink cartridges, which were a little stiffer than the square taper, and used a more reasonably sized Allen key.

External Threaded Bottom Brackets

Next came the external design, essentially where the bottom bracket is a hollow tube, secured into the frame using two cups threaded in externally on either side.

With the cups on the outside, the extra space could be used for more durable bearings and a wider, and therefore stiffer, spindle.

The spindle itself is removed from the bottom bracket entirely. Instead, it’s fused to the crank, which is simply slotted through the bottom bracket.

External threaded bottom brackets are the modern standard you should expect to see on most modern bikes. Shimano‘s Hollowtech II technology is one of the most popular examples.

Threaded Hollowtech bottom brackets use either English or Italian threading systems, referring to the diameter and the direction of the threads.

When fitting it’s vital to ensure your bottom bracket and frame are compatible. You also need to ensure your bottom bracket and cranks are compatible.

Pressed Bottom Brackets

Threading doesn’t work as well in carbon fiber, so as ultra-lightweight frames took off manufacturers began to rethink the bottom bracket.

Enter Cannondale’s BB30 in 2000, the first mainstream bottom bracket which was threadless, instead mechanically pressed directly into the bike frame.

These cups also sit further outside the bottom bracket shell, so with that extra space crank spindles can be even larger and stiffer.

Whilst these advances are certainly improvements, the pressing has to be near perfect or the bottom bracket will creak, badly. It’s also difficult for home mechanics to press their own cups without large and expensive tools.

And, crucially, threadless Hollowtech technology has birthed a wide range of varying cup sizes, or standards, so compatibility is… tricky.

See the standards below:

- BB30: Cannondale’s original propriety model, Specialized also uses this design, calling it OSBB.

- BB90 & BB95: These alternatives from Trek are identical to earlier external threaded bottom brackets, except pressed, so crankset compatibility remains the same.

- BB86 & BB92: Scott, Giant, and Pivot’s take on the BB90 & BB95.

- PF30 & Specialized OSBB: Improving on the BB30 model, the PF30’s press tolerance is a little more forgiving. Specialized OSBBs are used for mountain biking.

- BB30A & BB30-83 Ai: The BB30A uses an asymmetrical layout as the non-drive side shell is wider, and the BB30-83 Ai is asymmetrically wider still.

- PF30A & PF30-83 Ai: Essentially the same as the BB30A & BB30-83 Ai, but using bearing cups.

- BB386 EVO & BB 392 EVO: Even larger bearings that come with adapters for most crank sizes.

T47 Bottom Brackets

The T47’s introduction in 2015 saw the return of the threaded bottom bracket shell after years of criticism of pressed bottom brackets.

T47s thread or press into your frame with large bearings, they come as either internal bearings or external bearings which are even larger.

Specialized kits are used to adapt the T47 to various crank sizes.

Today you’ll find options for bikes using the T47 bottom bracket from various high-end manufacturers.

SRAM DUB Bottom Brackets

SRAM‘s DUB standard entered the market as a fix to the wide landscape of incompatible pressed bottom brackets.

By shrinking the spindle, DUBs are compatible with all existing bottom bracket configurations.

We’re all nervously excited for a future bottom bracket utopia of universal compatibility, and SRAM’s DUBs are a promising start.

Eccentric Bottom Brackets (EBBs)

Finally, as the name implies, EBBs are something of an oddball in the bottom bracket world: where all other models rotate around the bracket’s center point, EBBs rotate away from the center point.

More adapter than bottom bracket in its own right, your bottom bracket of choice is screwed into your eccentric bottom bracket.

The bracket’s spiraling movement can be adjusted by the user using a standard Allen wrench, and EBBs can be either threaded or pressed into your frame.

The function of this is to add chain tension without the use of a derailleur. They’re often favored on single-speed bikes.

Finding Compatible Parts

Now we’ve mapped the maze of bottom bracket standard types, how do you actually find the correct bottom bracket for your frame and crank when it comes time to replace?

You need to match the diameter and width of your frame’s bottom bracket shell to your bottom bracket standard. You’ll also need to check the thread directions on either side if applicable.

Then match the diameter and width of your bottom bracket to your crank.

Confirming six numbers fit into one another is a bit of a headache, and there are sometimes other “hidden” incompatibilities that you won’t notice from the sizing alone.

There are online resources that will cross-reference bottom brackets, frames, and cranks for you, and this makes the process easier.

From there it’s a case of finding the correct tools for the job, both removing your worn bottom bracket, and installing your replacement.

Again, this will require some research to find the right kit – or just a trip to your local bike shop.